Have you ever wondered how modern manufacturers keep everything running so smoothly behind the scenes? It’s not just about the big machines or the busy workers; it’s also about smart technologies like AIDC technology. How does AIDC technology perform in manufacturing, from your local car assembly line to global electronics producers? Let’s take a look.

Why AIDC Technology Matters More Than Ever

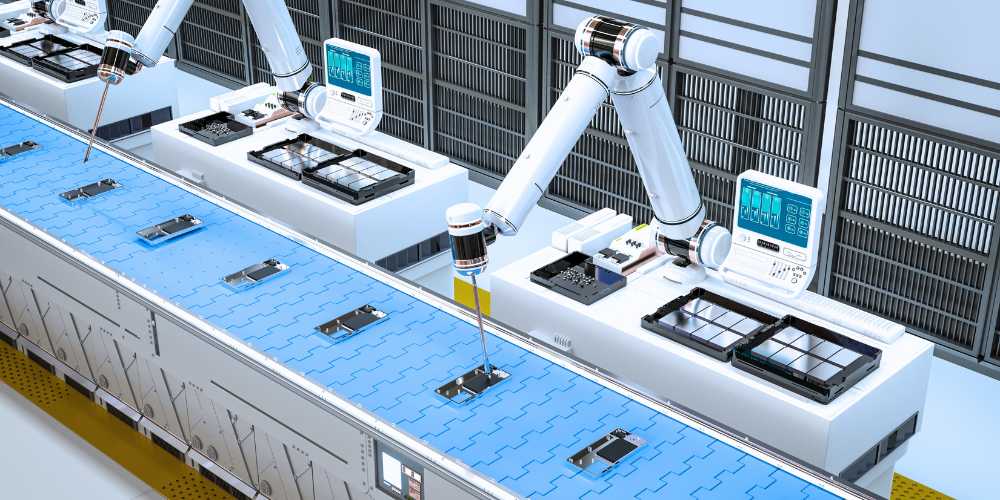

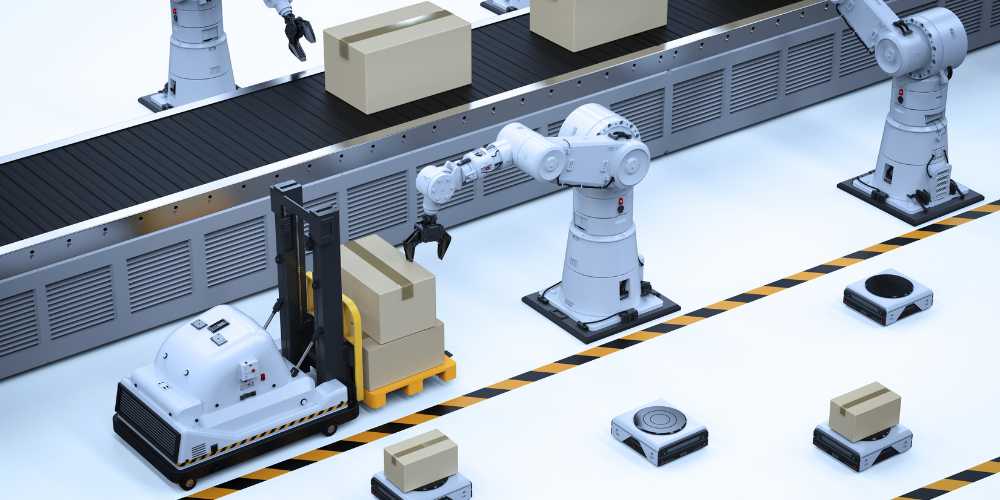

Imagine you’re running a factory that produces thousands of gadgets daily. Now, keeping track of every single component—like tiny screws and microchips—can be a nightmare without the right tools. That’s where AIDC technology comes in, with tools like barcode solutions for manufacturing and RFID in manufacturing making a huge difference. These technologies help eliminate human errors in data entry and speed up the whole process. No more missing parts or production delays!

RFID in Manufacturing: A Real-world Example

Let’s explore RFID in manufacturing further. Imagine a large automotive manufacturing facility where thousands of parts like windshields, tires, and electronics must be meticulously tracked and assembled. With RFID tags, managers can instantly locate specific parts stored anywhere in their vast warehouses. For example, if an assembly line suddenly needs a new shipment of airbags due to a recall, RFID technology allows the team to quickly find and route those specific parts to the right place without delay. It’s not just about efficiency; it’s about being responsive and adaptable in a high-stakes environment, which RFID in manufacturing makes possible.

Barcode Solutions for Manufacturing: Simplicity in Action

Now, let’s expand on barcode solutions for manufacturing with another scenario. Consider a textile manufacturer that produces a wide range of fabrics, from cotton blends to high-tech synthetics. Each roll of fabric gets a unique barcode that tracks its journey from weaving through dyeing to final shipping. Scanning barcodes allows the staff to monitor which batches of fabric are undergoing chemical treatment, which are ready for quality control, and which are packaged for shipment. This method not only streamlines workflow but also helps in managing inventory levels more effectively, ensuring that popular materials are always in stock.

Choosing the Best AIDC Solutions for Improving Manufacturing Efficiency

Selecting the right AIDC solutions can feel daunting, but it’s all about what fits your operation best. Whether it’s implementing versatile barcode solutions or robust RFID systems, the key is to enhance what you already do without flipping your processes upside down. The best systems grow with your business, adapt to your needs, and deliver results without disrupting the established workflow.

Let’s Wrap It Up: Future-proof Your Manufacturing with AIDC

So, whether you’re a small operation starting out or a seasoned manufacturer looking to upgrade, integrating AIDC technology is like setting the GPS for a successful, efficient production journey. Ready to reduce errors, save time, and control your inventory like a pro? It’s time to think about how AIDC technology can fit into your manufacturing strategy. Contact us now or explore other manufacturing solutions to help your business!